Follow-up on sushi tuna scrape: it’s supposed to be cooked!

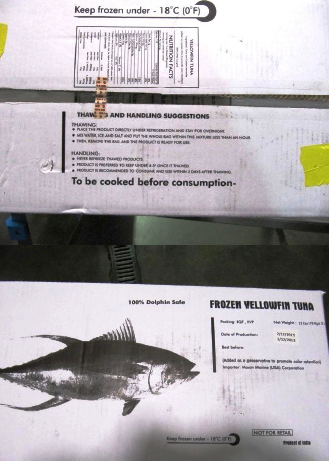

In response to my post on tuna scrape, Professor Alan Reilly, Chief Executive, Food Safety Authority of Ireland (the equivalent of our FDA) sent this photograph of an actual tuna scrape label.

After I forwarded it to Bill Marler, he noticed that it is one of several photographs posted on the FDA’s tuna scrape recall web page).

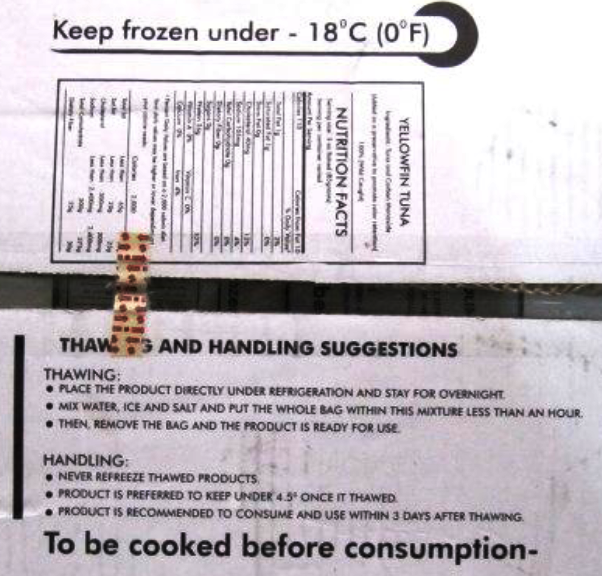

The type is too small to read so I’ve done some cropping:

Professor Reilly asks:

What is puzzling me is why this product “minced tuna” was used in sushi products. The label (copy attached) clearly states that the product must be cooked before consumption and it is for industrial uses only (labelled not for retail).

Those are good questions, but here’s another, equally alarming. What’s that strangely formatted Nutrition Facts label? It does not precisely follow FDA design or content requirements.

This is a red flag. If the company is not following labeling rules, it might not be following other rules either—safety, for example.

Safety? Uh oh.

Bill Marler reports that the FDA “483 Inspection Report” on the Indian tuna processing facility is now available. Read these quotes and shudder:

- Tanks used for storage of process waters have apparent visible debris, filth and microbiological contamination.

- There is no laboratory analysis for water used in ice manufacturing at the [redacted] facility to show the water used to make ice is potable.

- Apparent bird feces were observed on the ice manufacturing equipment at Moon Fishery; insects and filth were observed in and on the equipment.

- Tuna processed at your facility, which is consumed raw or cooked, comes in direct contact with water and ice.

I draw several lessons from this episode:

- Food is safer when cooked.

- Labels need to be read—and followed—carefully.

- Raw sushi is a high risk product, especially if it doesn’t cost much.

- The FDA needs to be doing a lot more inspecting of overseas facilities, and before they cause problems.

All of this means that we need a better food safety system, one that can address the enormous proportion of our food supply that comes to us from countries with weaker food safety standards.

Addition, May 17: Ben Embarek, a food safety scientist at the World Health Organization notes that the 483 report reveals that Moon’s HACCP plan did not list appropriate critical control points. Anyone auditing the plan should have picked up the problems on paper, which is easier and less expensive to do than an on-site inspection. But the FDA does not pre-audit international HACCP plans. They are supposed to be cleared by exporting companies registered by FDA. Comment: it’s hard to imagine that the current system can work, and it clearly does not.